Circular seam welding machines for tanks, hydrocylinders, piston rods, air compressors, extinguishers, transmission shafts, dampers, mufflers, flanges

1. Specification of Circular seam welding machines for tanks, hydrocylinders, piston rods, air compressors, extinguishers, transmission shafts, dampers, mufflers, flanges

| Models | Workpieces |

Rated capacity (kw) |

Range of compressed air (mpa) |

Voltage (v/hz) |

||

|

TKS (mm) |

Length (mm) |

Dia. (mm) |

||||

| NTCS-800 | 0.8-30 |

≤800 |

60-300 | 0.15-5.5 | 0.2-0.8 |

AC380/50 Customized |

| NTCS-1000 | 0.8-60 |

≤1000 |

100-500 | 0.15-5.5 | 0.2-0.8 |

AC380/50 Customized |

| NTCS-1500 | 0.8-60 |

≤1500 |

160-600 | 0.15-5.5 | 0.2-0.8 |

AC380/50 Customized |

| NTCS-2000 | 0.8-80 |

≤2000 |

160-600 | 0.15-5.5 | 0.2-0.8 |

AC380/50 Customized |

| NTCS-3000 | 0.8-80 |

≤3000 |

160-600 | 0.15-5.5 | 0.2-0.8 |

AC380/50 Customized |

| NTCS-6000 | 0.8-100 |

≤6000 |

200-800 | 0.15-5.5 | 0.2-0.8 |

AC380/50 Customized |

| can be customized | ||||||

2. Characteristics of Circular seam welding machines for tanks, hydrocylinders, piston rods, air compressors, extinguishers, transmission shafts, dampers, mufflers, flanges

(1) Programmable logic controller, data set by touch screen, convenient to operate.

(2) The movement of torches and workpieces is driven by servo motors. The actions are precise. torches swing automatically and precisely, welding starts and finishes at right points.

(3) The welding types are optional according to thickness & types of tank sheets. They can be MAG (Metal Active Gas), PAW (Plasma Arc Welding), SAW (submerged Arc Welding).

(4) The welding is taken automatically and it doesn't require the wokers have any welding skills.

(5 One worker is enough to operate it.

(6) The welding looks beautiful, strong, and full like it is done by a skilled welder.

(7) The torches can be set with one, two or more and can be cooled by water or air.

(8) Laser monitors are optional according to the shapes of welding seam.

(9) Multi-layer multiple welding can be also achieved.

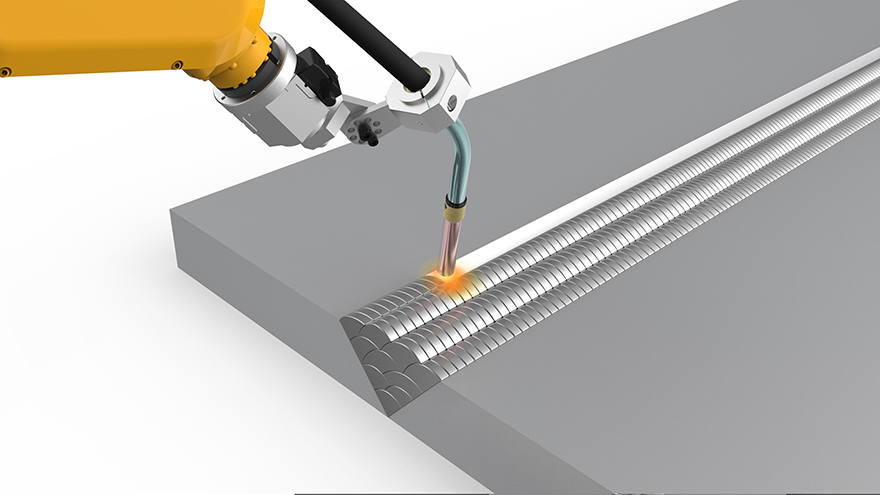

multi-layer multiple welding

3. Application

Circular seam welding machines are used to make water heaters' tanks, water or gasline tanks, pressurized vessels, extinguishers, air compressors, solar water heaters, hydrocylinders, transmission shafts, damples, muffles, piston rods, the connection of pipes to pipes, pipes to flanges, etc.

4. Take a look at the welding video of Circular seam welding machines for tanks, hydrocylinders, piston rods, air compressors, extinguishers, transmission shafts, dampers, mufflers, flanges as follows:

-

How to Make Stainless Steel Water Tanks

How to make stainless steel water tanks with our machines? There are 7 steps.

넶569 2022-05-31 -

What are the advantages of your welding machines for stainless steel water tanks?

There are our own technology and designs on our welding machines for stainless steel water tanks and others. Ourselves-made inverter controllers make the welding machines save at least 30% electricity.

넶299 2022-06-07 -

How to make insulated stainless steel water tanks

Insulated stainless steel tanks are used to keep water warm or cool. Then how to make them by our machines?

넶234 2022-06-07 -

What are the difference between ordinary non-inverter AC welding machine and our inverter controlled ones?

This article is to let you know more about our inverter controlled welding machines

넶77 2022-06-08